Choose your option

Choose your option

Choose your option

Choose your option

Choose your option

Choose your option

Choose your option

Choose your option

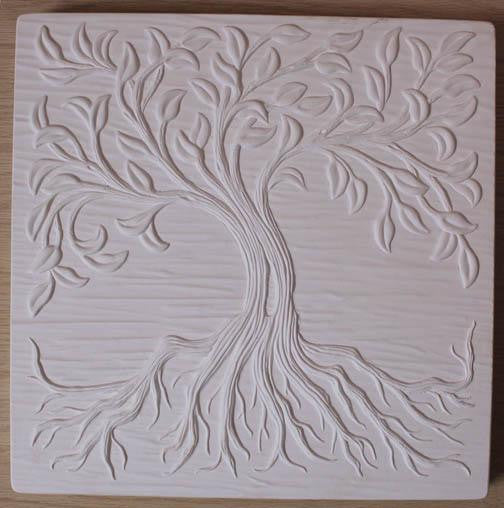

Tree of Life Sprig Mold TX20

Regular price

$44.00

Sale price

$44.00

Regular price

$44.00

Choose your option

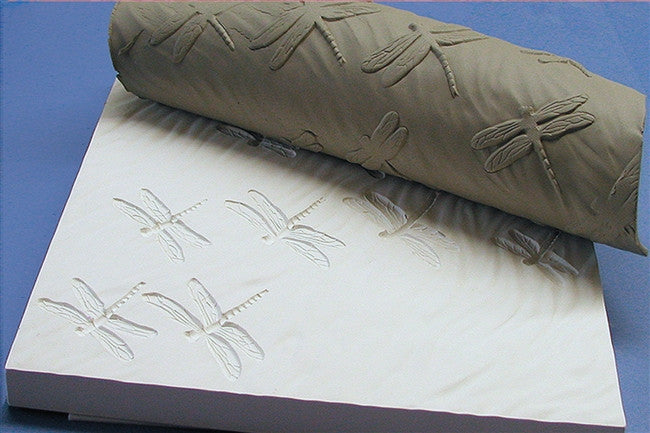

Dragonfly Texture Mold TX18

Regular price

$43.75

Sale price

$43.75

Regular price

$43.75

Choose your option

Choose your option

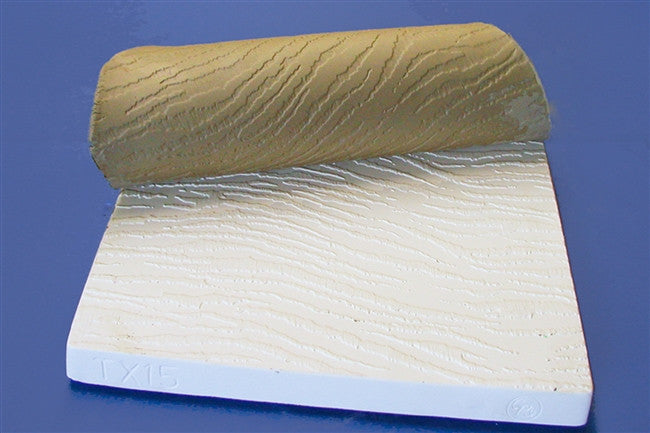

Hot Patterns Texture Mold TX13

Regular price

$44.00

Sale price

$44.00

Regular price

$44.00

Choose your option

Tortoise Shell Texture Mold TX19

Regular price

$44.00

Sale price

$44.00

Regular price

$44.00

Choose your option

Choose your option

Choose your option

3 Round Hollow die for 5 Extruder

Regular price

$33.00

Sale price

$33.00

Regular price

$33.00

Choose your option

Tribal Diamond Texture Mold TM2

Regular price

$43.65

Sale price

$43.65

Regular price

$43.65

Choose your option

Choose your option

Lemons Flexi-bat

Regular price

$30.00

Sale price

$30.00

Regular price

Choose your option

Damask Flexi-bat

Regular price

$25.00

Sale price

$25.00

Regular price

$30.00