Amaryllis - Mayco SW Crystals 192

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Aurora Green - Mayco SW Crystals 146

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Black Timber Pint - Mayco SW Crystals 220

Regular price

$17.00

Sale price

$17.00

Regular price

$17.00

Choose your option

Blue Hydrangea - Mayco SW Crystals 170

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Blue Splatterware - Mayco SW Crystals 152

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Celadon Bloom - Mayco SW Crystals 150

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

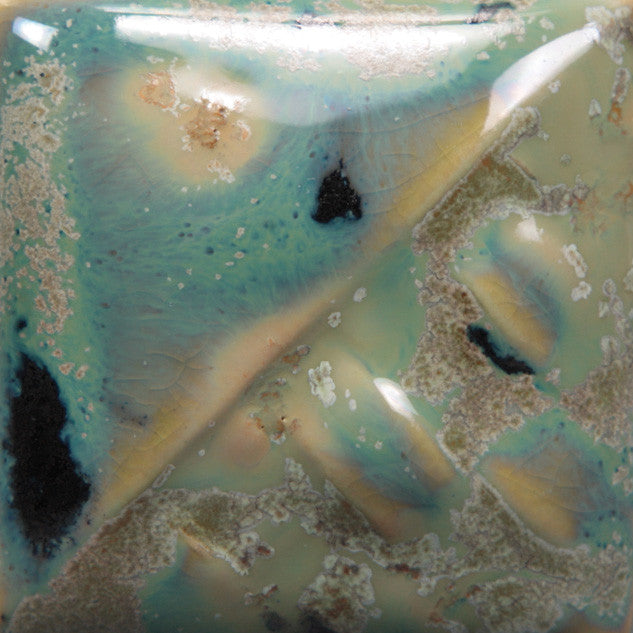

Cenote - Mayco SW Crystals 189

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Cinnabar Pint - Mayco SW Crystals 119

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Desert Dusk - Mayco SW Crystals 180

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Enchanted Forest - Mayco SW Crystals 171

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Galaxy - Mayco SW Crystals 156

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Green Jasper Pint - Mayco SW Crystals 222

Regular price

$17.00

Sale price

$17.00

Regular price

$17.00

Choose your option

Honeycomb - Mayco SW Crystals 117

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Indigo Rain - Mayco SW Crystals 153

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Lime Shower - Mayco SW Crystals 148

Regular price

$17.00

Sale price

$17.00

Regular price

Choose your option

Micro Ash - Mayco SW Crystals 218

Regular price

$15.25

Sale price

$15.25

Regular price

Choose your option

Micro Cerulean - Mayco SW Crystals 217

Regular price

$15.25

Sale price

$15.25

Regular price

Choose your option

Micro Champagne - Mayco SW Crystals 215

Regular price

$15.25

Sale price

$15.25

Regular price

Choose your option

Micro Jade - Mayco SW Crystals 216

Regular price

$15.25

Sale price

$15.25

Regular price

Choose your option

Micro Pearl - Mayco SW Crystals 214

Regular price

$15.25

Sale price

$15.25

Regular price