Laguna Pacifica GT400

Regular price

$1,340.00

Sale price

$1,340.00

Regular price

$1,523.50

Choose your option

Choose your option

Shimpo VL-Lite with Splashpan

Regular price

$1,070.21

Sale price

$1,070.21

Regular price

$1,216.15

Choose your option

Quark S+ Wheel

Regular price

From $575.00

Sale price

From $575.00

Regular price

$668.50

Choose your option

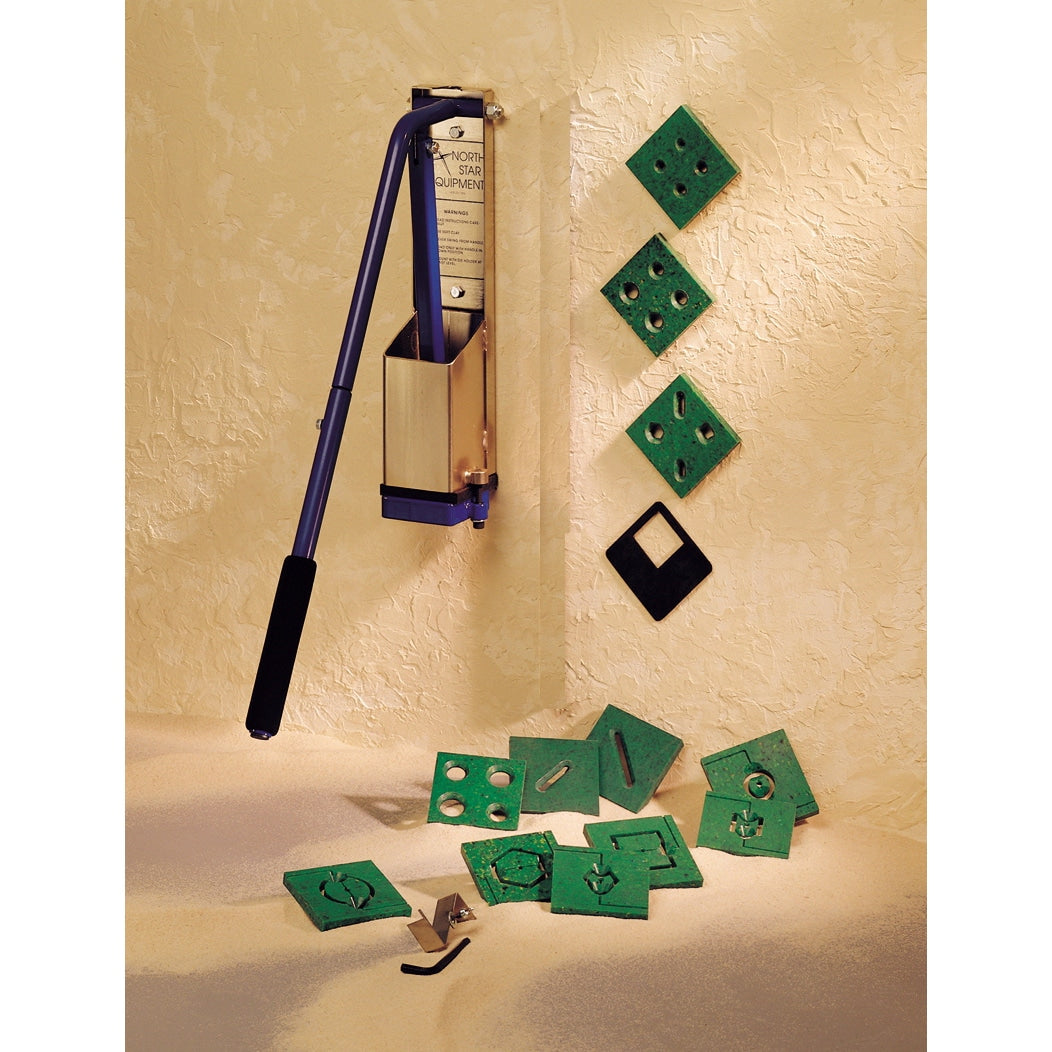

North Star Stainless Steel Extruders

Regular price

From $626.99

Sale price

From $626.99

Regular price

$659.99

Choose your option

Brent Model C Electric Wheel with Splash Pan

Regular price

$2,376.00

Sale price

$2,376.00

Regular price

$2,700.00

Choose your option

Shimpo VL-Whisper with Splashpan

Regular price

$1,878.33

Sale price

$1,878.33

Regular price

$2,134.47

Choose your option

Choose your option

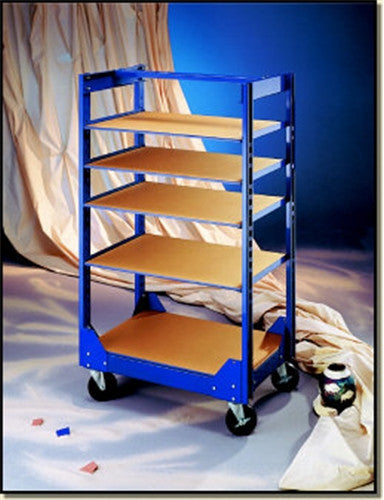

North Star Shelf Truck Package

Regular price

$1,397.99

Sale price

$1,397.99

Regular price

$1,315.99

Choose your option

Laguna Pacifica GT800

Regular price

$1,580.00

Sale price

$1,580.00

Regular price

$1,798.50

Choose your option

Shimpo NRA-04 Pugmill

Regular price

From $5,082.41

Sale price

From $5,082.41

Regular price

$6,116.32

Choose your option

Coneart 119 with Genesis Controller

Regular price

$2,816.00

Sale price

$2,816.00

Regular price

$3,200.00